Description

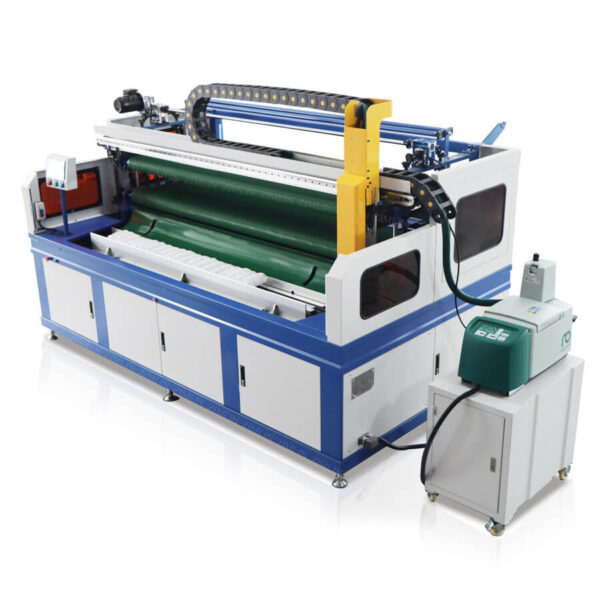

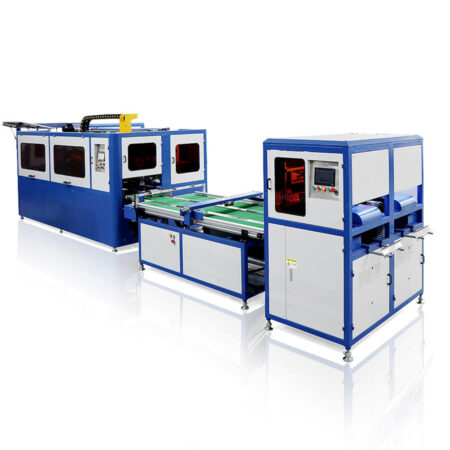

This semi automatic pocket spring assembly machine used for assembling pocket spring unit via extruding glue through the nozzle to the spring rows, and upper and lower non woven covers. Adopting touch screen, the machine is easy to operate, highly auto with stable performance and well-glue effect.

▲

After the springs are produce by the pocket spring machine and cut springs. Then, this machine nozzles spray glue to form the springs into rows. Then combine into mattress sized shape. It also the most important part of the mattress.

▲

In detail, we adopts imported PLC control system. Moreover, it use servo controlling the glue spraying point. Not only with high automation but also stable work performance. In addition, You can choose USA Nordson or switzerland robatech and more. Not only with high automation but also stable work performance. .

▲

The machine can be used for assembly of drum type or cylindrical pocket spring. And adhesion of strip pocket springs can be realized in parallel or cellular forms. Intermittent glue spraying can save the glue cost by over 40%. In addition, this machine can choose whether adhesion of the upper and lower non-woven cloth is require.

Support remote control the following subject

- a. Monitoring program.

- b. Online auto repair function.

- c. Program modification.

- d. Update the machine system.

Semi Auto Pocket Spring Assembly Machine Features

- 1. High speed production about 6-8 rows per min.

- 2. The servo conveying mattress, size precision.

- 3. Four glue nozzles can be individually controll.

- 4. Adopts photoelectric safety protection function.

- 5. Continuous spray and spot spray 2 glue spray mode options.

- 6. Easy to operate and maintain.

TECHNICAL PARAMETERS

| Model | JK-AS1 |

| Productivity | 7-9rows/min |

| Glue Box | USA Noordson/ Spain Merlot/ Robatect |

| Glue Spray | Spot spray or continuous spray |

| Girder | Servo drive |

| Demand of Gas Supply | 0.25m³ /min |

| Working Pressure | 0.5-0.6 mpa |

| Spring Placement Method | Manual placement |

| Total Power | 7KW |

| Input Voltage | 3AC380V |

| Frequency | 50/60 Hz |

| Weight | 2600 KG |

| Adhesive bed nets width | Maximum width of 2200 |

| Width of Non-Woven Fabric | 2300mm |

| Thickness of non-woven fabric | 50-100g/ m² |

| Spring height | 60-300mm |

| Size Lenght | length3.8m, Width 1.8m, Height 2m |