We all want to relax after a full day’s hectic routine. The only place we can see clearly is the bed where we lie down. So, if that bed’s fabric, structure, and formation make you uncomfortable, you won’t leave with any choice but to change the mattress.

On the contrary, if your mattress provides you great comfort and perfectly hugs when you lie down so, you may want to know what mattress machinery is used to manufacture it. This is something that will fascinate you. Don’t worry; you are covered. This article is worth reading information that will cover all the steps a mattress spring goes through and become a utility product. So, without wasting any time. Let’s get straight into it.

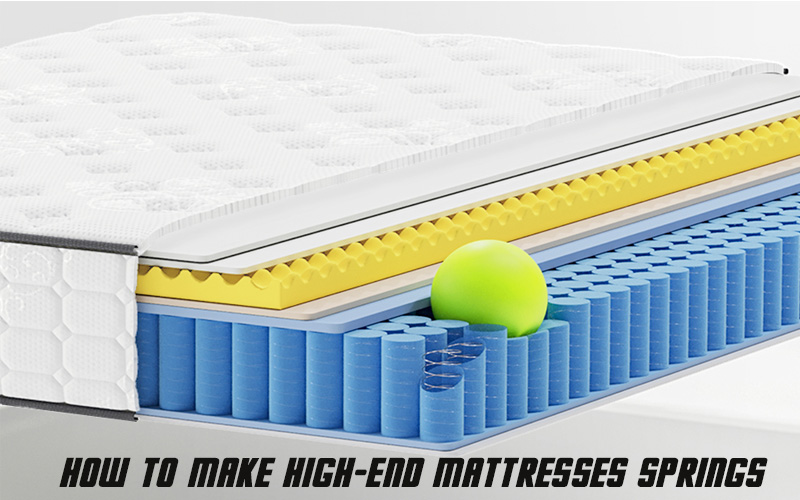

High-Quality Mattress Springs.

These are the premium quality springs that are used in luxury mattress structures. The springs are diligently designed with the help of a pocket spring machine (equipment to form the pocket and wrapped coils) that is highly flexible, resistant, and ultra-durable. Unlike the conventional springs, these are manufactured to provide the user with great comfort and a soothing feel.

They evenly distribute the body weight and encourage spine alignment while sleeping.

Mattresses containing these springs actively respond to the sleeper’s movements and contouring and accordingly adapt their body shape to create a personalized comfort experience that relieves the pressure points.

Steps of manufacturing high-end springs in a factory.

A series of steps are generally followed to manufacture the springs in a production unit.

The following steps will interest the users about the product they are currently using.

Selecting a wire

The first step begins with the proper selection of steel wire. Since the whole structure relies on the type of wire, you choose. The steel wire must comply with quality standards to ensure its reliability, stretching, and elasticity, ultimately affecting the spring’s performance. The wire is always bought from official dealers to get the best quality.

Wire coiling

In this step, the selected wire is fed into a particular coiling machine that shapes the wire into separate coils that continue to form the base of mattress springs. This specialized device is completely customized and can be adjusted based on the type of wire you want to design.

Heating process

Once the coils are shaped appropriately, the springs undergo the heating treatment, also known as “Tempering.” The coil springs are heated at high degrees and instantly cooled down during this process. This technique aims to empower the springs and test their resilience so they can withstand the compression and decompression they will experience later.

Assembling the springs

As soon as their temperature becomes normal, springs are assembled into mattress units with the help of pocket spring assembly machine. Usually, different types of spring assemblies are widely used in high-end mattresses, such as Bonnell, pocketed, and continuous coil systems.

Bonnell Springs

Bonnell springs are interconnected using helical wires; since these wires are threaded from top to bottom, rows of springs continue to form a network of springs that work together to provide robust support.

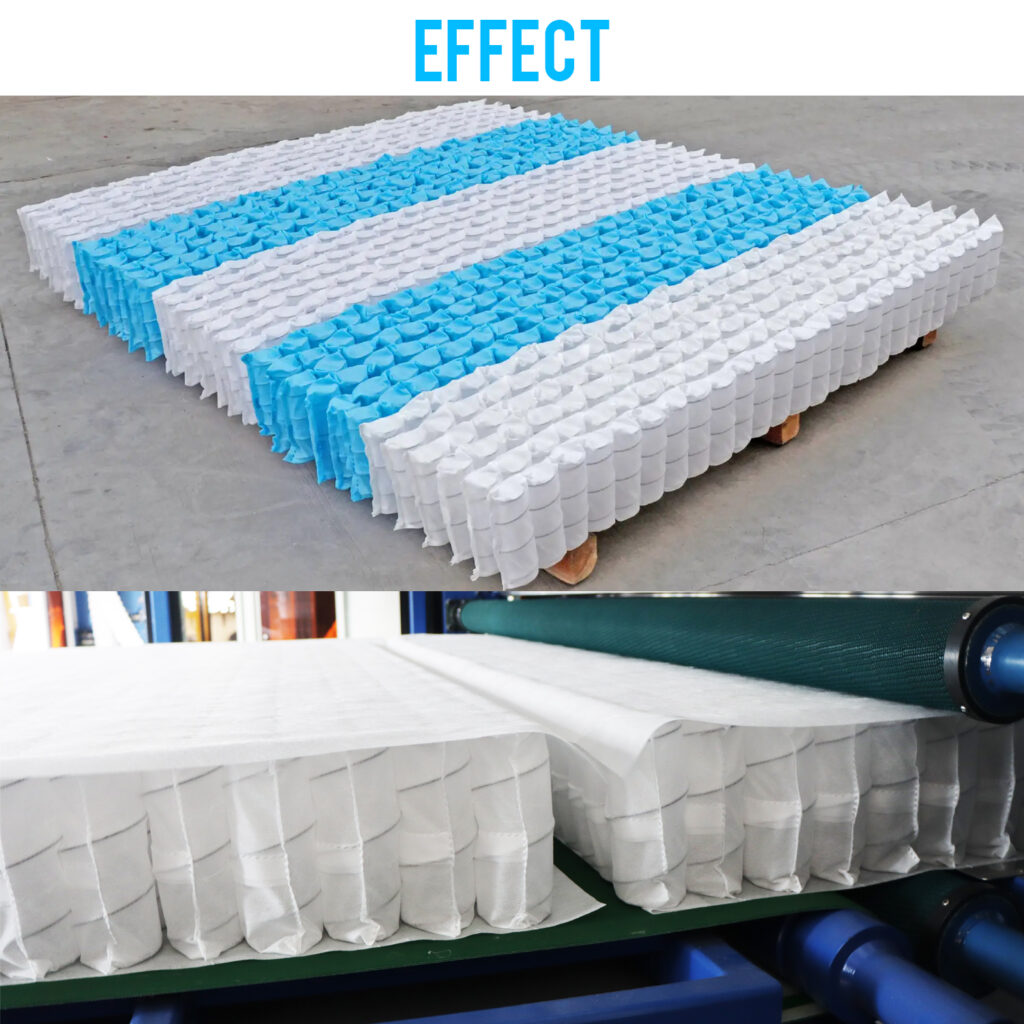

Pocketed Springs

These springs are primarily individual coils encased in fabric pockets. Every spring is surrounded by its own fabric pocket that allows it to work independently from the rest of the springs. This basic design is great for better motion isolation and targeted support.

Continuous Coil Spring

They are formed by a single long wire bent into a series of S-shaped loops. The loops are attached, shaping a spring row. Continuous springs are best to enable consistent support across the mattress surface.

Attaching the border wire

Later on, a thick type of gauge wire, often called a ‘border wire,” is connected to the perimeter of the spring unit to empower the mattress with additional stability and comfort and prevent it from sagging.

Spring encasement

Until now, the manufacturing process is almost done, but a few steps remain. The mattress springs are now encased, which can be fabric or non-woven material. The enclosure helps to protect them and boost the spring’s comfort layers.

Now, each step is covered with great attention to detail, and then springs are sent forward for quality clearance check. After this check, they get clearance and are sent for distribution and packaging. This is how a factory executes steps to design the springs.

What is the age of high-end mattress springs?

Generally, high-end springs last 8 to 12 years and even more (if used carefully). Even though this period can even be reduced or increased depending on your usage. If you use the mattress recklessly, it’s predictable that it won’t last more than 2 to 3 years.

By using carelessly, you start seeing the signs of wear earlier due to your lack of care. Adequate maintenance helps to extend their longevity and maximize performance.

Are Spring mattresses really comfortable for patients?

Spring mattresses are undoubtedly an excellent option for patients due to their high comfort and resilient springs. A patient with back, shoulder, spine, and cervical issues can consider this incredible technology for reliving their muscle strains effectively.

Even though there are other choices in the market for patients, such as foam, gel, and air mattresses. It depends what’s your budget; based on the pricing, you can get a comfortable mattress that will transform your way of sleeping.