Description

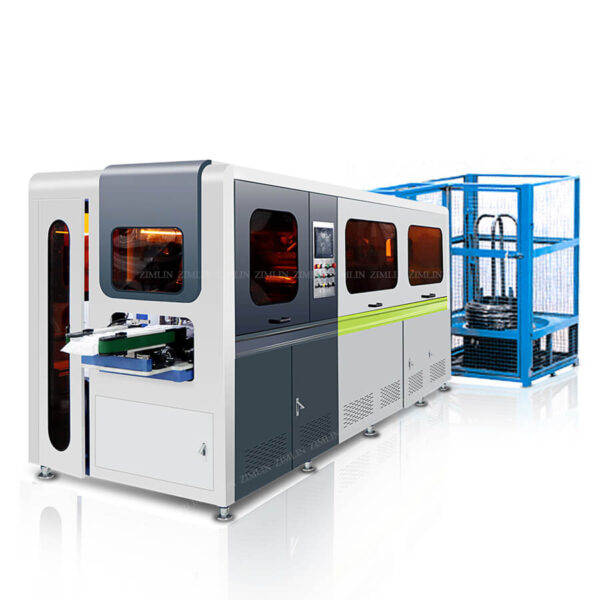

This automatic pocket spring machine normal production speed can reach 200 springs per minute, top production speed can reach 220 springs/min. Fastest production speed so far.

Let’s briefly describe. The steel frame transmits the wire into the machine, then winds and shapes it, finally cooled and wrapped with non-woven fabric to form a pocket spring. This is how the machine works.

The Four Main Process

- a. The spring coiling

- b. Heat treatment

- c. Non-woven fabric folding

- d. Ultrasonic welding

The whole machine adopts safety protection function, we are safer when using. In addtion, we adopts advance motor drive to be efficient, stable and precise. Only need one people to operate this machine. Not only high output but also saving cost. It is your the best choice for the production of pocket spring.

Pocket Spring Machine Features

- 1. Production speed 200-220 springs/min.

- 2. Missing spring alarm reminder.

- 3. Mechanical failure alarm prompt.

- 4. Spring disorder detection alarm.

- 5. Wireframe will automatic wire speed increase and decrease speed.

- 6. Tight ultrasonic welding.

- 7. High-power cooling device, good spring forming effect.

- 8. Adopting 3 layer spring conveying method, it is will not burn the non-woven fabric.

- 9. Automatic counting in system, record daily production output automatically.

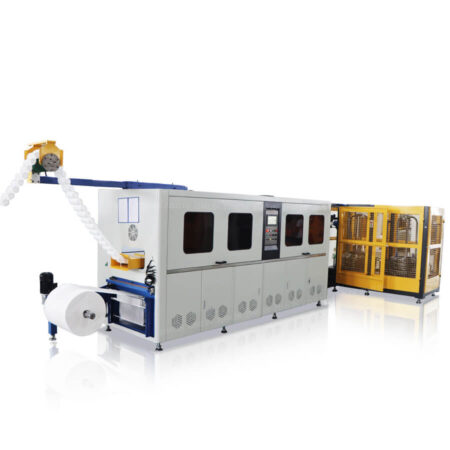

Complete Production Line

Finally, we are still need a pocket spring assembly machine to assembling the spring to form mattress network. We offer 3 types of assembly machine can be connected with 2 ~3 pocket spring machines to form a production line.

Technical Parameters

| Model | JK-PS-200 |

| Efficency | 200-220 springs/min |

| Non-Woven Supply | 60-100g/m² |

| Pocket Spring Height | 100-250mm |

| Wire Dia. | Ø1.6mm-Ø2.3mm |

| Spring Core Dia. | Ø55mm-Ø80mm |

| Non-Woven Width | 340mm-680mm |

| Power Supply | 23KW |

| Total Power | 38KW |

| Voltage | 220V/380V/50HZ |

| Air Requirement | 0.02 m³/min 0.8 MPa |

| Gross Weight | 3500KG |

| Overall Dimension | 5550mm×1500mm×1950mm |

KIMKOO Mattress Machinery