Description

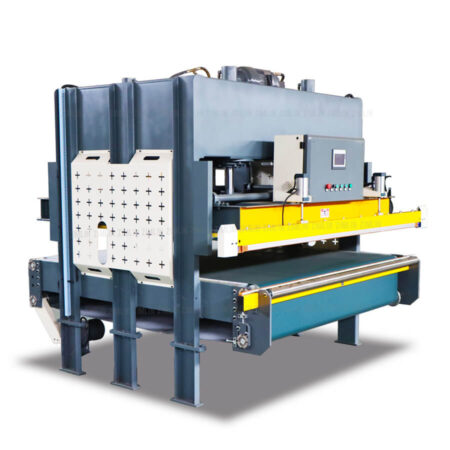

Introducing our foam block compression machine, meticulously designed to compress foam/foam blocks, offering a remarkable 95% volume reduction. This not only enhances storage convenience but also results in substantial savings on storage space and shipping costs.

Key Features

- Maximum Compression: Achieve a 95% reduction in volume, allowing for efficient storage and cost-effective shipping.

- Manual Bagging: Prior to compression, manual bagging of foam blocks is necessary using PE bags to ensure safe and effective compression.

- Heat Seal Technology: The compressed foam blocks are transformed into a flat shape through heat sealing, creating a secure and sealed state.

- Impressive Travel Distance: The press plate boasts a travel distance of up to 1300mm, enabling the compression of foam blocks with a maximum height of 1300mm. Of course, we also accept customization and customize a higher itinerary.

Main Functions

- Compression: Efficiently compress foam blocks.

- Heat Seal: Utilize heat sealing technology for a secure seal.

Professional Compression System: Our machine adopts a professional PLC control system, ensuring high safety standards with an emergency stop switch function. The compression process is swift, completing packaging in just 35 seconds. The low packing cost significantly reduces labor expenses, providing cost-effective and flawless packaging.

Versatile Volume Reduction: Achieve an impressive 23:1 ratio of volume reduction, allowing for the compression of different foam blocks into flat-pack shapes. The machine ensures the integrity of your product, preventing deformation or damage during the compression process.

Outstanding Features

- High Pressure: The machine exerts a substantial pressure of 120Tons, ensuring effective compression of foam blocks.

- Swift Process: The entire foam block compression and packaging process takes only 30 seconds.

- PLC Control and SIEMENS Accessories: Adopting advanced PLC control and quality SIEMENS accessories for precision and reliability.

- Ease of Operation: User-friendly operation with an operational video and manual provided.

- Floating Working Table: Enhancing ease of operation, making the compression process more accessible.

- Stability and Durability: The machine is built to be stable and durable, ensuring longevity in your operations.

Experience the Efficiency: Contact us to arrange a product test on our JK-C3 machine and witness the remarkable results achieved through our innovative foam block compression technology. Elevate your foam handling processes with precision, speed, and cost-effectiveness.

TECHNICAL PARAMETERS

| Model | JK-C3 |

| Power of oil pressure | 5.5kw |

| Dimension(L*W*H) | 3900*(2500+2700)*3400mm |

| Distance of the opening gear | 1200mm |

| Number of air cylinder | 10pcs |

| Pumping power | 4kw |

| Net weight | 4500kg |

| Voltage | 380V/50Hz |

| Heating power | 3kw |

| Working pressure | 120T |

| Number of oil cylinder | 4pcs |

| Size of pressure plate | 2300*2500mm |