Description

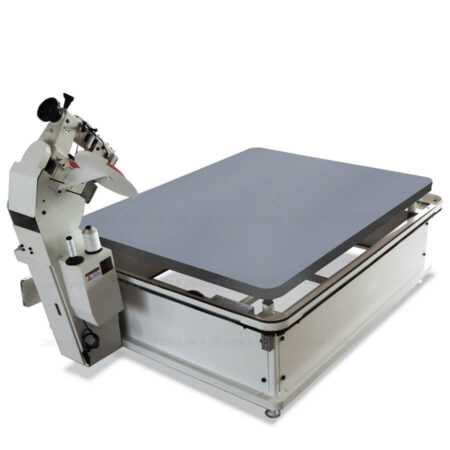

This fully automatic mattress tape edge machine is mainly used to finish the top and bottom edges sewing of a mattress, with auto flipping function and conveyor belt.

Above all, fully automatic tape edge machine makes your sewing operations easier. With auto flipping function and conveyor belt, the productivity will be greatly improved. The operator does not need to move with the mattress, but only needs to stand next to the control panel and the sewing head to complete the whole process, which means more time saving. In addition, with the PLC control system, the sewing speed is adjustable and the sewing effect is perfect. In addition, stable performance and easy to operation can meet the needs of most modern people, the best assistant for your mattress edge sewing.

Automatic Mattress Tape Edge Sewing Machine Features

- 1. More than 18 mattresses/hour

- 2. (30mm – 550mm) mattresses sewn with ease

- 3. High speed Singer 300U chain stitch sewing head

- 4. Auto-flip facility

- 5. Pneumatics foot lift

- 6. Sewing head tilt 40° adjustable angle

- 7. Auto deceleration at corners

- 8. Sewing speed can be adjusted

- 9. Max speed up to 3,500rpm

- 10. Rugged steel frame construction

- 11. We not only provide Install video but also detailed install manual

- 12. In addition, we accept customization

TECHNICAL PARAMETERS

| Model | JK-T4 |

| Application | Tape edge sewing, taping |

| Efficiency | More than 18 mattresses/hour |

| Mattress Thickness | (30-550) mm |

| Sewing head tilt maximum angle | 40° |

| Power | 2-Phase, 220V, 50HZ & 3-Phase, 380V, 50HZ |

| Total Power | 3 KW |

| Air Supply | (0.7-1.0) Mpa |

| Total Weight | 1300 Kg |

| Condition | New |

| Table Size | 3800*2000*870 mm |

| Machine Size | 3800*2650*2400 mm |