Description

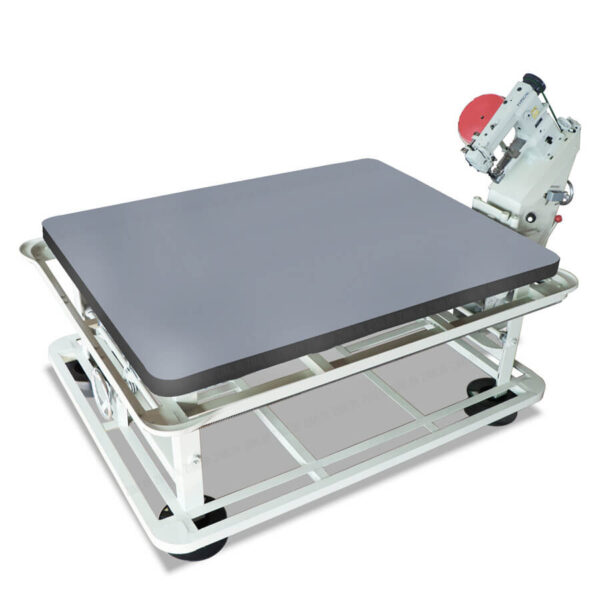

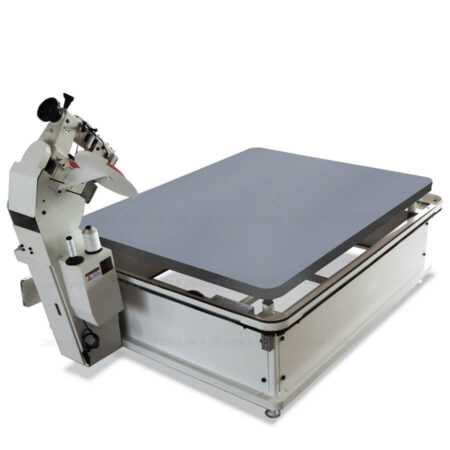

Manual Mattress Tape Edge Sewing Machine Application

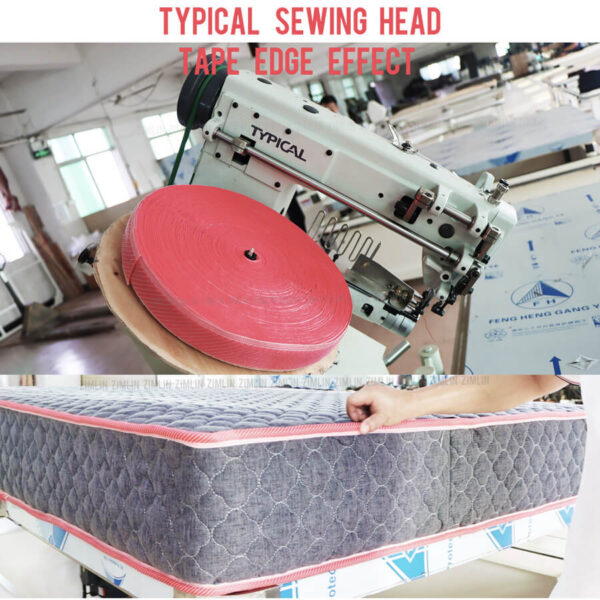

This manual mattress tape edge sewing machine is mainly used to finish the top and bottom edges sewing of a mattress. Our machine adopts lock stitch sewing method. It means a sewing machine stitch formed by the looping together of two threads one on each side of the material being sewn. This is a relatively primitive sewing method, but it is still use by many people. In contrast, chain stitch has the better performance.

Drive Mode

It requires manual lifting of the workbench, as well as manually adjusting the sewing head angle. Electronically driven sewing head. In short, its variable-speed drive motor includes an automatic slow-down and is perfect for cornering and selectable speed ranges.

Features

- 1. Lock stitch Typical/Seiko sewing head for choice.

- 2. Highly-precise guide rail.

- 3. The machine working table can be adjusted between 0-260mm according to your requiment.

- 4. High effective, average 15 units mattresses/hour.

- 5. The sewing speed is adjustable, and it will decelerate automatically when it reaches the corner.

- 6. Not only low noise and low vibration but also stable performance.

- 7. We provide install manual and Install video.

- 8. Easy to operate.

- 9. In addition, we accept customization.

Mattress Tape Edge Machine Parameters

| Model | JK-T1 |

| Application | Mattress tape edge sewing |

| Sewing thickness | 30-550 mm |

| Head travel distance | 0-200 mm |

| Workingtable lifting range | 0-260 mm |

| Total power | 1.5KW |

| Power | 2-Phase,220V/380V/50HZ |

| Efficiency | 15 units/h |

| Total weight | 400kg |

| Workingtable size | 2000*1600 mm |

| Machine dimensions | 2100*1600*820 mm |

| Condition | New |