Description

This 240 springs /min micro pocket spring machine (double wire) is mainly used for sofa, all types box spring pad and mattress…

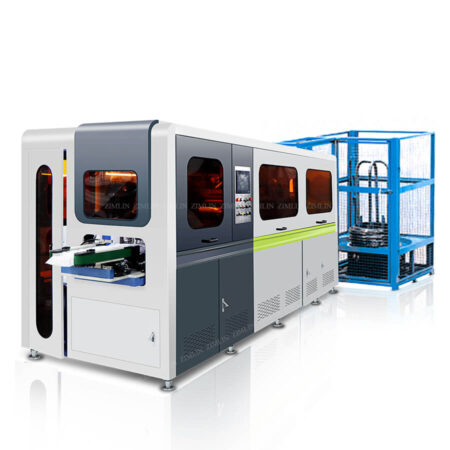

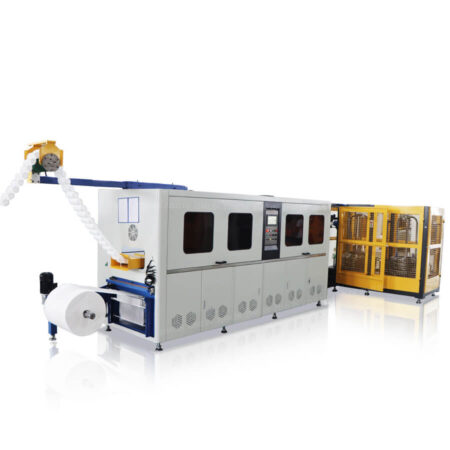

Micro Pocket Spring Machine for Sofa

We adopts microcomputer numerical control technology. And independent research and development of the control system. Equipped with spring beating device, bagging device, ultrasonic welding device, fabric conveying device, etc., to achieve assembly line operation, is the best choice for the production sofa and box spring pad.

THE FOUR MAIN PROCESS

- a. The spring coiling.

- b. Heat treatment.

- c. Non-woven fabric folding.

- d. Ultrasonic welding.

SPRING ZONING

Double wire micro spring machine means our machine at the same time can produce different size steel wire and spring core diameter, that is zoning function. It means that a box spring pad can exist two different pocket springs simultaneously. The size of the spring wire determines the softness of the spring. This allows for spring zoning based on comfort needs as well as body parts.

FEATURES

- 1. Production speed 240 springs /min.

- 2. Double wire coiling head.

- 3. Can achieve box spring pad zoning.

- 4. Missing spring alarm reminder.

- 5. Mechanical failure alarm prompt.

- 6. Spring disorder detection alarm.

- 7. CE Standard.

- 8. ZIMLIN Patent Product.

TECHNICAL PARAMETERS

| Model | JK-BS-240 |

| Product Name | Micro Pocket Spring Machine |

| Production capacity | 240pcs/min |

| Average power | 10.5Kw/hour |

| Total power | 15KW/hour |

| Input current | 3phases,380V, 4 wires |

| Air consumption | 0.4mpa |

| Frequency | 50/60HZ |

| Fabric density | 60-90g/m2 |

| Fabric width | 200-300mm |

| Wire diameter | 1.0-1.8mm |

| Spring waist diameter | 30-50mm |

| Pocket spring height | 20-40mm |

| Main machine size | 5700mm*2000mm*2100mm |

| Total size | 9500mm*2200mm*2500mm |

| Weight(Approx.) | 8000KG |

| Servo Motor | Detal |

| PLC/Touch screen | Delta |