In the high-stakes world of global furniture logistics, shipping bulky products is expensive and often inefficient. If you want to reduce mattress shipping costs, you need a smart, technology-driven strategy for mattress logistics optimization. Traditional shipping methods, which involve transporting “expensive air,” are no longer sustainable for modern e-commerce. In this comprehensive mattress roll packing guide, we explain exactly how to pack mattress for shipping to maximize container utilization and protect your profit margins.

By utilizing high-performance mattress packing machine technology, manufacturers can compress products by up to 90%. This results in a direct 70% reduction in shipping and storage expenses. Below, we will dive into the most advanced mattress packing solutions and provide a detailed mattress machine comparison between our flagship models.

The Advantages of Roll Packed Mattresses: Why You Need Compression

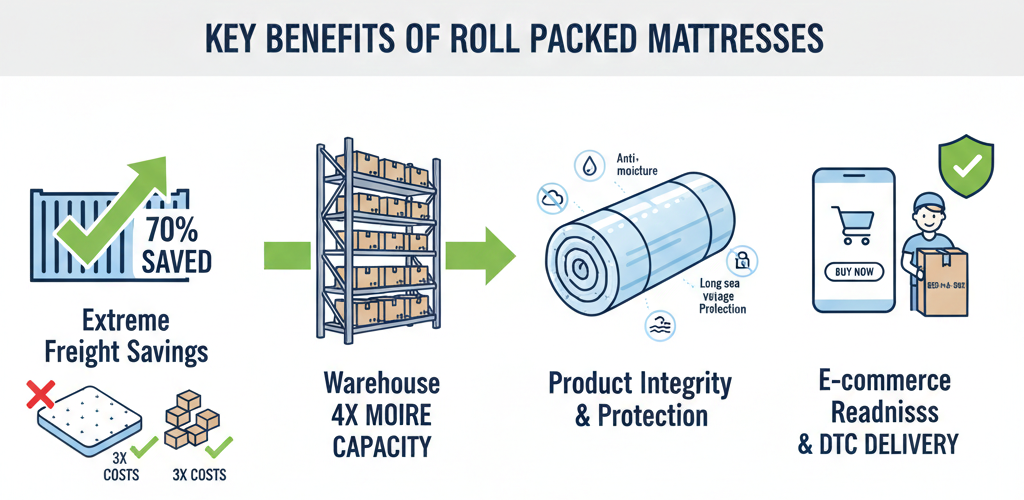

Understanding the core mattress compression benefits is the first step toward scaling your global business. The advantages of roll packed mattresses go far beyond just saving money on freight; they redefine your entire supply chain. By implementing an automated mattress packaging process, you solve four critical industry bottlenecks:

- Extreme Freight Savings: Dimensional weight pricing can triple your costs for uncompressed products. Compression eliminates this penalty.

- Warehouse Optimization: A roll-packed mattress takes up only 1/4 to 1/5 of the space, effectively quadrupling your inventory capacity.

- Product Integrity & Protection: Using heavy-duty PE or PVC bags with airtight heat sealing protects against moisture, dust, and odors during long sea voyages.

- E-commerce Readiness: Compact rolls are ideal for “Bed-in-a-Box” delivery services like Amazon or direct-to-consumer (DTC) shipping.

Technical Comparison: JK-CR1 vs. JK-CR06

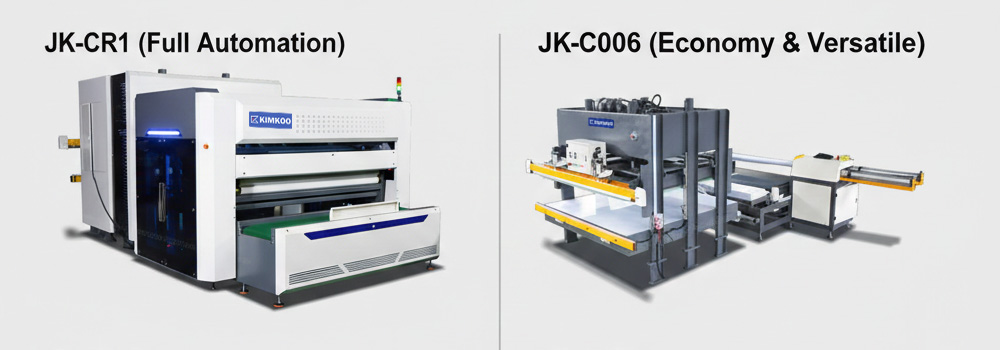

Choosing the best mattress roll packing machine depends on your production volume and product diversity. Both machines are designed to reduce mattress shipping costs, but they serve different operational scales.

| Feature | JK-CR1 (Full Automation) | JK-CR06 (Economy & Versatile) |

| Target User | High-volume Factories / E-commerce | Mattress / Sofa & Foam Manufacturers |

| Automation Level | Fully Integrated PLC System | Semi-Automatic (Manual Transfer) |

| Cycle Time | 30 – 35 Seconds per unit | 50 – 60 Seconds per unit |

| Hydraulic Pressure | 100 Tons | 50 Tons |

| Customization | Specialized for Mattresses | High-Clearance for Sofas & Foam |

| Key Advantage | Maximum Speed & ROI | Low Investment & Multi-product |

High-Performance Solution 1: JK-CR1 (Premium Automated Mattress Packaging Process)

The JK-CR1 Mattress Compression & Roll Packing Machine is the gold standard for high-volume automation. It is the ultimate mattress packing solution for manufacturers aiming to reduce mattress shipping costs with zero human error.

Intelligent Control & Precision

Equipped with a SIEMENS touchscreen panel and PLC control system, the JK-CR1 ensures stable operation. It doesn’t just roll; it thinks. The system automatically adjusts the roll diameter based on the actual mattress size and thickness, ensuring a tight, optimized fit every time. This precision is vital for a successful mattress roll packing guide implementation.

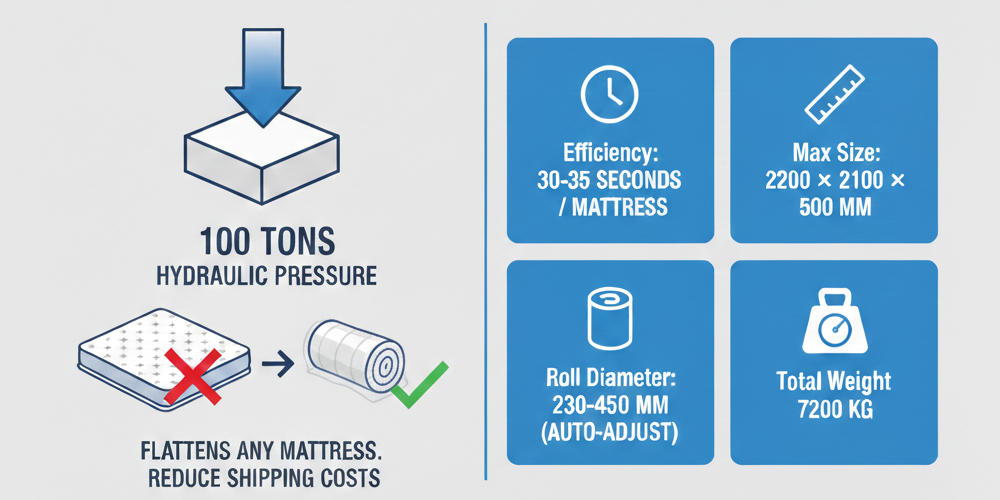

100 Tons of Raw Compression Power

At the heart of the JK-CR1 is a heavy-duty hydraulic system that applies 100 tons of pressure. This ensures that even the thickest pocket spring or high-density foam mattresses are flattened perfectly before the automated mattress packaging process begins, allowing you to reduce mattress shipping costs significantly.

JK-CR1 Technical Specs:

- Efficiency: 30-35 seconds per mattress.

- Max Mattress Size: 2200mm × 2100mm × 500mm.

- Roll Diameter: 230 – 450 mm (Automatically adjusted based on mattress size).

- Total Weight: 7200 KG.

Versatile Solution 2: JK-CR06 (Economy Model for Diversified Production)

If you are looking for how to pack mattress for shipping while also handling other upholstered products, the JK-CR06 is the industry’s most flexible economy mattress packing solution.

Beyond Mattresses: The Sofa & Foam Solution

The JK-CR06 Compression & Roll Packing Machine for Mattress, Foam & Sofa (Economy Model) stands out because it isn’t limited to mattresses. With a customizable compression height of up to 1.0 meter, it is the ideal machine to reduce mattress shipping costs for bulky items like sofas, foam blocks, and stacked foam layers. This versatility makes it a top contender in any mattress machine comparison.

Simple and Reliable Operation

This model integrates the JK-C1 compression unit with the JK-R1 rolling unit. The process is straightforward for achieving mattress logistics optimization:

- Manual Bagging: Product is placed in a PE/PVC bag.

- 50-Ton Compression: Flattening and airtight heat sealing.

- Manual Transfer: Easy movement to the rolling axis.

- Electric Rolling: Precision rolling into a compact cylinder.

The ROI Calculation: Why Now is the Time to Invest

Investing in a mattress roll packing machine is not an expense; it is a financial strategy. Most manufacturers find that the ability to reduce mattress shipping costs allows the machine to pay for itself within a very short period.

- Triple Your Shipping Capacity: A standard 40HQ container that once held 50 mattresses can now hold 150+ units after utilizing these mattress packing solutions.

- Damage-Free Technology: Our machines are engineered to ensure mattresses return to their original shape within 3 seconds—zero deformation, 100% mattress compression benefits.

Explore More Specialized Solutions

Looking for a machine that can handle more than just standard mattresses? We provide a wide range of solutions for the entire upholstered furniture industry. Check out our category for specialized sofa, foam, and mattress compression machines: https://szkimkoo.com/product-category/sofa-foam-mattress-compression-packing-machines/

Conclusion: Choosing the Best Mattress Roll Packing Machine

Whether you choose the high-speed JK-CR1 for its automated mattress packaging process or the JK-CR06 for its versatility, KIMKOO ensures you achieve total mattress logistics optimization. We are committed to providing the best mattress roll packing machine technology to help your business dominate the global market.

As a leading manufacturer with over 18 years of expertise, KIMKOO is dedicated to providing the most reliable mattress machine solutions in the industry. Ready to scale your production and reduce mattress shipping costs? Contact our engineering team today for a professional consultation and a custom quote!