Description

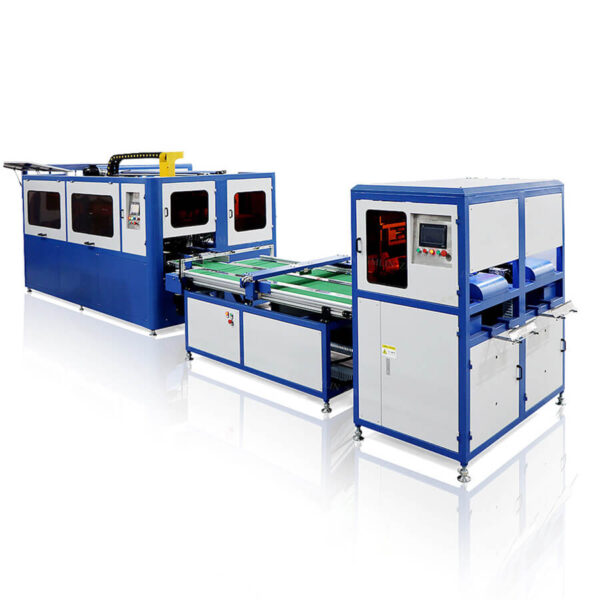

This 1-2 version automatic pocket spring assembly machine can connect with 1pcs or 2pcs pocket spring machine (to produce springs) at the same time. Our machine equipped with 2 channels can be selected to match 2 high-speed pocket spring coiling machine produces at the same time.

A mattress net is formed through a series of processes, such as producing pocket springs, cutting the spring row of corresponding length, adhesive spraying the spring row, and bonding the non-woven fabric up and down. Without doubt, all steps can be complete in this machine.

Assembly Types

- a. Longitudinal

- b. Lateral

- c. Parallel

- d. Nested

- e. Duplex

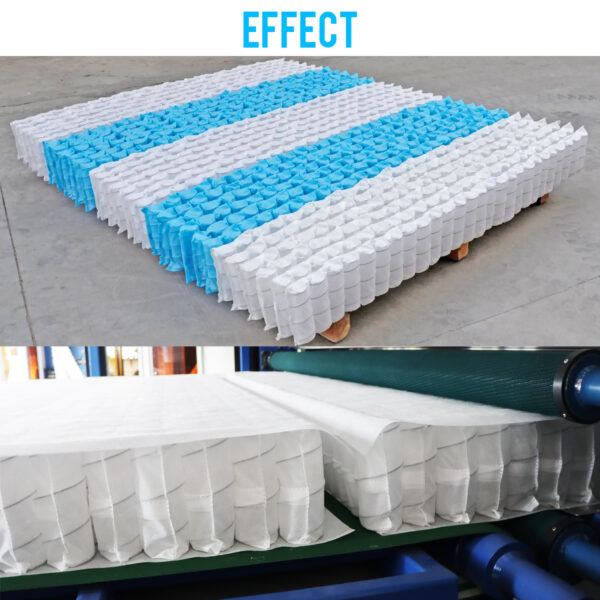

Zoned Pocket Spring Units

Automatic zoning pocket spring units. Through this machine, we can input matress net zoning parameters in the PLC control system, which can accurately control each spring unit. And fully automatic production of zoning spring units.

What does zoned pocket spring units mean? It means that a mattress can exist 2 or more different pocket springs simultaneously . And the size of the spring wire determines the softness of the spring. This allows for spring zoning based on sleep needs as well as body parts. It greatly improves the comfort of sleep and people also get healthy sleep.

Automatic Pocket Spring Assembly Machine Features

- 1. High speed production, each mattress net can be produced at the high speed of 2.5-4 min(14 rows of springs/min).

- 2. Allows online help support, such as computer remote failure analysis.

- 3. Imported PLC control system, accordingly, servo control can saves more glue.

- 4. Precise automatic ultrasonic welding and cutting.

- 5. Automatic calculation of the number of spring, precise length cutting.

- 6. Automatic zoning pocket spring units.

- 7. Auto upper and lower fabric cutting device.

- 8. Material depletion auto stop sensor.

- 9. Continuous spray and spot spray 2 glue spray mode options.

- 10. Multiple fault detecting device.

- 11. High safety, the whole machine adopt special protection device.

TECHNICAL PARAMETERS

| Model | JK-AS2 |

| Productivity | 14 rows/min |

| Plastic box | Spanish Merlot /Robuck/American Nordson |

| Plastic tank capacity | 8.8KG/15KG/20KG/30KG |

| Spraying mrthod | Point spray and continuous spray |

| Height adjustment | 140-250mm(automatic adjustment) |

| Operational application | Automatic zoning, automatic cloth feeding, automatic spring feeding, automatic cutting |

| Total Power | 10KW |

| Input voltage | 3AC380V |

| Input Current | 40A |

| Input cable | 5×6mm² |

| Frequency | 50/60Hz |

| Air demand | 0.25m³ / min |

| Working Pressure | 0.5-0.6 mpa |

| Size Length | length4300mm, Width 3000mm, height 1900mm |

KIMKOO Mattress Machinery