One of the most common concerns of mattress manufacturers regarding mattresses is their packaging once they are manufactured. Poor and unprotected packing ultimately consumes more space, impacts the brand’s credibility, and becomes a hurdle in transferring the products to retail stores for sale.

Well, this issue has been resolved with the help of a roll pack and mattress compression machine that efficiently compress the mattress for robust handling that prevent potential damages and satisfy customers. This article will share some essential aspects of the advanced packaging system and its benefits. So, without any further ado. Let’s get straight into it.

What exactly is a smart mattress packaging system?

Unlike traditional processes, it’s a technologically advanced system integrated with automation primarily designed to enhance the packaging methods. It’s a relatively more tailored and customized solution for every type of mattress to shape and fold without any hassle.

Multiple types of machines are used in this process; it varies from company to company and their style. Roll pack machine is one of the latest machines used for such tasks in most industry sectors due to its multiple features such as compression and rolling mechanism, adjustable parameters, and conveyor system, making it super easy to operate and speed up the process.

How does the smart packaging system work?

This is an exciting step where the mattress is packed with a hot seal and ready to load in the truck in just a few steps.

The following are the typical steps through which a mattress is packed efficiently.

Customizing the machine setting: The first step is to set the machine setting depending on your mattress type. This smart system is programmed and configured based on the commands you give to the machine. The most common settings you will adjust like the type of mattress, dimensions, and other custom options you want to enable. There is a list of different settings, such as compression timing and seal, so you get control and operate it effectively.

Automated loading: The machine has been adjusted regarding our instructions. It’s time to load the mattress. A conveyor belt is installed so the bed can be placed on it to go through different packaging stages, even though you can do this manually or use automation.

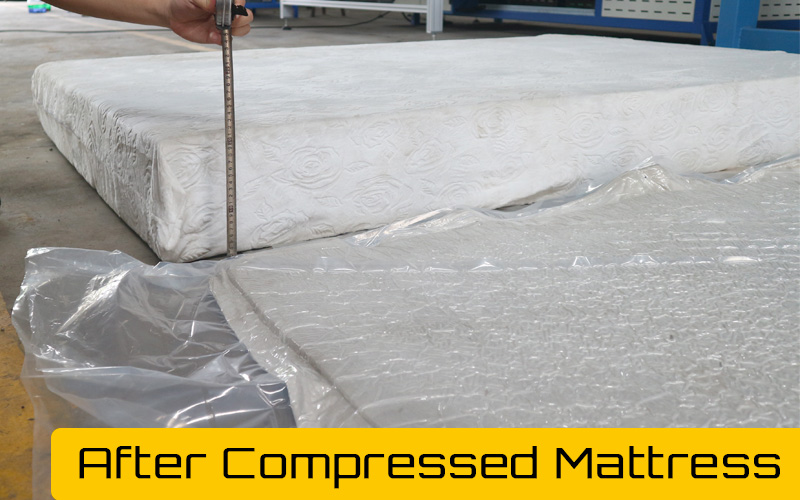

Compression: After it is positioned in an adequate setting, the system proceeds with compression. This process is usually performed with the help of hydraulic and mechanical systems that put pressure on it to lessen its thickness. Reducing thickness is essential, as it’s hard to transfer it because it needs more space to adjust, which is not a suitable option for companies.

Rolling: In this step, the mattress gets rolled after being compressed effectively. The rolling machines tightly roll it completely from one end to another to create a compact and cylindrical shape for more convenience.

Sealing and packing: Each step has been followed in perfect order. Now the mattress is in our desired shape. Still, the process is uncompleted. It has to get sealed and packed in plastic wrap. As the machine is programmed, it performs the step on its own. You don’t have to pull or push it away for sealing and packaging. The system simply releases it through a hole within in a wrapped form that workers pick and ultimately load.

Benefits that companies get with the advanced packaging system

There are multiple that customers and manufacturers both get to send and receive the product in a secure environment.

Complete Protection: Do you want a mattress full of scratches and utterly damaged? Of course! You don’t want that. That’s why they are transferred intact to ensure the best possible arrangement and ultimately reach the customer safely.

During transportation from different locations, the chances of damage, getting dust, moisture, and other complicate situations are increased. Sometimes, the fabric gets scratched, all the foam inside gets contaminated, and springs become useless. With smart packaging, these hindrances are easily removed.

Space Saving: Without compressing them appropriately, these matters can get workers in trouble managing them in a perfect arrangement. As they are considerably vast in width and length. So, by compressing them, the space can easily be customized. It enables the mattress to load and unload efficiently, ease inventory, and streamline logistics.

Beyond all things, it is beneficial when storing it in the warehouse. It’s simple to understand; the less space it takes to keep, the less you have to pay.

Brand Availability: Mattress packaging is primarily a visual representation of the brand that manufactures it. An attractive and professionally designed packaging symbolizes the mattress’s worth and makes it appear more professional to customers. So, the more quality and appealing it looks, the more company increases its credibility.

How long does the mattress packaging usually last?

It’s an interesting question; generally, the packaging is meant to last until the wrap is covered. Once the protective layer is removed, it is discarded entirely. But it’s pretty uncommon since the mattress travel to diverse locations; there are chances that the protective layer may not be in good condition after a while. Still, companies ensure they send the product intact without any damage to satisfy their customer and get a 5-star rating.

Conclusions

If you are a manufacturer, you must be concerned with the roll pack machine packaging mechanism, as it’s an essential part of the process. Additionally, you as a business appear more professional and credible that people trust, and you build long-term ties with them.