When you lie down on a mattress, the support you feel is often the result of decades of engineering evolution. Among the various internal structures, the bonnell spring system remains the most enduring and widely recognized foundation in the bedding industry. Whether you are a consumer asking about a bonnell spring mattress meaning or a factory owner researching how to manufacture a bonnell spring unit, this guide will provide the 10x depth you need.

Part 1: Decoding the Bonnell Spring Mattress Meaning

To understand the bonnell coil mattress meaning, we must look at the “Hourglass.” Unlike modern pocket springs, a bonnell spring unit is a classic innerspring structure where multiple steel coils are interconnected with a mesh of metal wires.

What defines a Bonnell system?

- Hourglass Shape: Each individual bonnell coil unit is wider at the top and bottom than in the middle. This design ensures that the spring reacts linearly to weight—the more pressure you apply, the more resistance it provides.

- Interconnected Support: Unlike independent coils, every spring in a bonnell spring system is tied to its neighbor via a helical wire. This creates a unified “spring bed” that offers a firm, traditional feel.

For consumers, the bonnell spring mattress meaning translates to durability and consistent support. It is the “workhorse” of the mattress world—reliable, breathable, and capable of lasting decades without sagging.

Part 2: How Does a Bonnell Spring System Work?

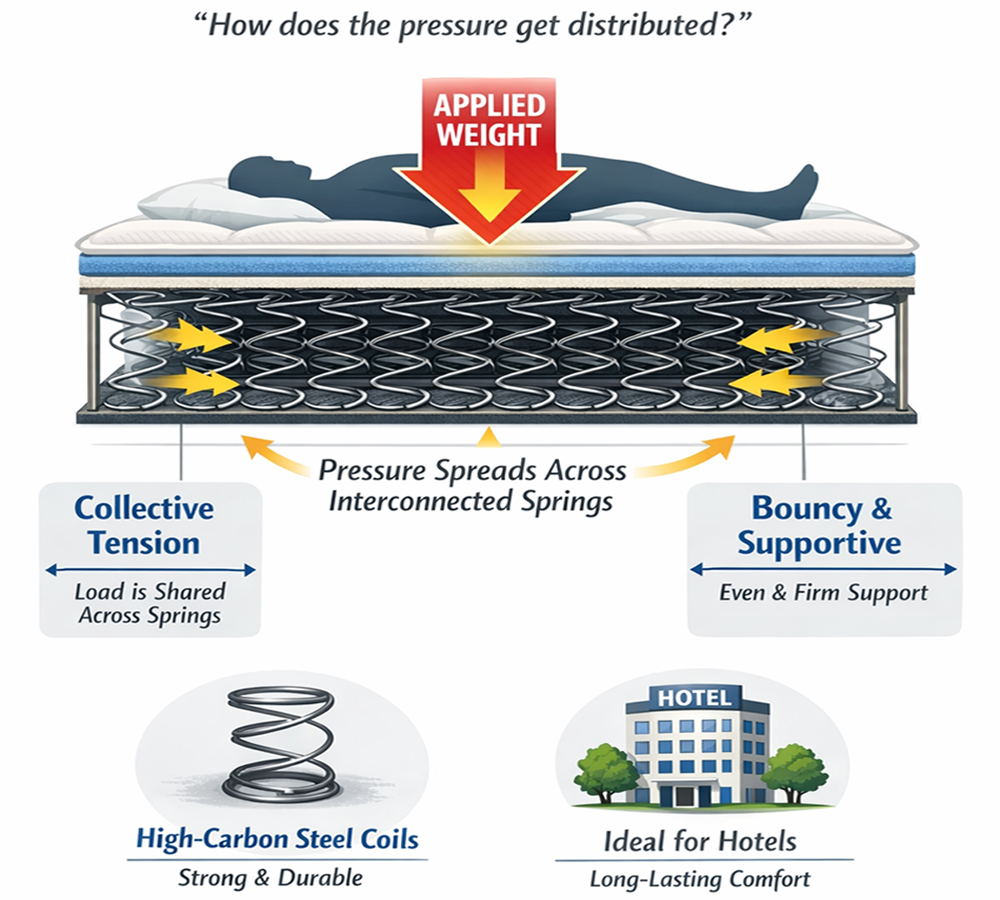

Many people ask, “How does a bonnell spring system work in terms of ergonomics?” The secret lies in the collective tension.

When weight is placed on a bonnell spring unit, the pressure isn’t just absorbed by one coil; it is distributed across the entire rows of interconnected springs. This is how a bonnell spring unit work to provide that signature “bouncy” feel. Because the coils are made of high-carbon steel, they offer excellent rebound force, making them ideal for users who prefer a firm sleeping surface or for hospitality environments like hotels where longevity is key.

Part 3: Why Bonnell Spring Units Still Dominate the Global Market

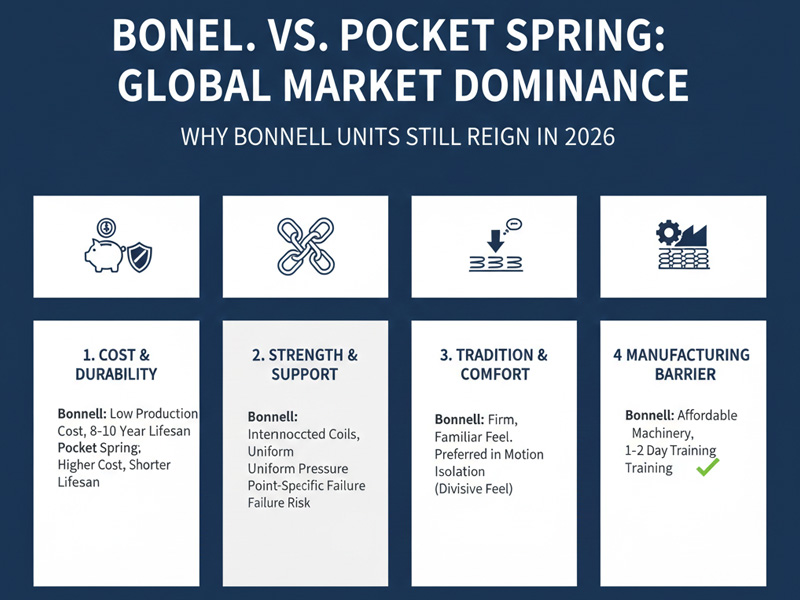

In 2026, despite the marketing hype around pocket springs, the bonnell spring system remains the undisputed king of the global mattress industry. Why? Because it solves the real-world problems of both manufacturers and consumers.

1. Unbeatable Cost-Efficiency & Durability

Let’s talk money. A bonnell spring unit is far more affordable to produce than a pocket spring unit. It offers a “premium feel” at a fraction of the price. For the average family, it is the most practical choice—economic yet incredibly durable. A well-made Bonnell mattress can easily last 8 to 10 years without losing its integrity.

2. Superior Strength through Interconnected Support

One of the biggest misconceptions is that “independent” is always better. In a bonnell coil system, every spring is interconnected. When pressure is applied, it isn’t just one coil fighting the weight—the force is distributed across the entire rows of springs.

- The Logic: If one pocket spring fails, the mattress sinks at that point. But because Bonnell springs share the load, the entire unit remains stable and supportive for much longer.

3. The Power of Tradition & Sleep Habits

Human habits are hard to change. Millions of people have grown up sleeping on the firm, uniform support of a bonnell spring mattress. Switching them to a softer or “independent” feel often results in back discomfort or poor sleep. For many markets, the “Bonnell feel” is the only definition of a good night’s rest.

4. Low Manufacturing Barrier (Easy to Start)

From a production standpoint, the barrier to entry is low. Unlike complex pocket spring lines, the machinery for a bonnell spring system is affordable and straightforward.

- Simplicity: Whether you use a manual setup or our automatic bonnell spring coiling & assembly machine, the learning curve is short. With just 1–2 days of training, a worker can become proficient. This makes it the perfect choice for factories looking to scale quickly without high labor or equipment costs.

Part 4: How to Manufacture a Bonnell Spring System (The Professional Way)

For manufacturers, the real question is how to manufacture a bonnell spring system that meets international quality standards while maintaining high efficiency.

Manufacturing a high-quality bonnell spring unit requires a seamless transition from raw steel wire to a finished helical-bound core. At KIMKOO, we specialize in the engineering of bonnell spring machines that eliminate manual errors and maximize output.

The Step-by-Step Production Process:

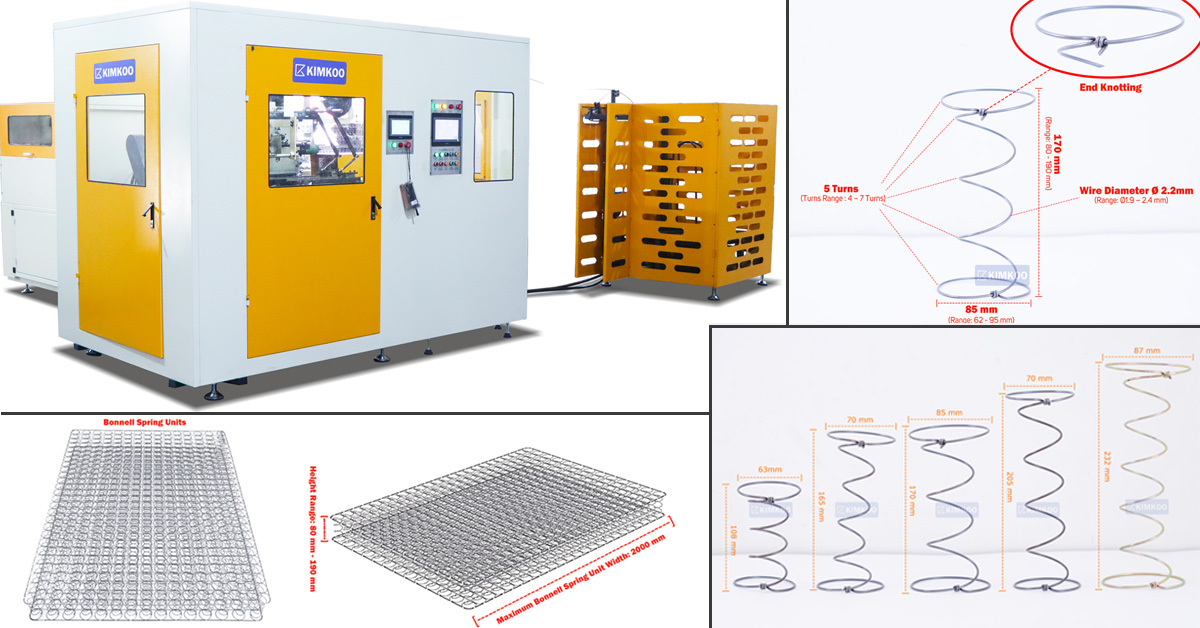

- Coiling: High-carbon steel wire is fed into a bonnell spring coiling machine. Our CNC coiling head, driven by Japanese Tamagawa servo motors, shapes up to 90 springs per minute.

- Knotting & Heat Treatment: Both ends of the coil are knotted for stability. Then, an integrated electric heat treatment strengthens the “coil memory,” ensuring the mattress won’t deform over time.

- Assembly: The individual coils are transferred via a six-manipulator mechanism to the bonnell spring assembly machine. Here, helical wires (spiral wires) are threaded through the rows of springs to lock them into a single, unified unit.

Part 5: The Technology Behind the JK-BSA01 Fully Automatic Line

If you are looking for how to manufacture a bonnell spring unit at an industrial scale, the KIMKOO JK-BSA01 is the industry benchmark. This is a fully integrated system that combines coiling, knotting, tempering, and assembly into one streamlined workflow.

Why Leading Factories Choose KIMKOO Equipment:

- Precision Control: Equipped with WECON dual touchscreens and PLC control, you can adjust spring height (80mm–230mm) and turns (4–7 turns) with digital precision.

- High Output: Achieving up to 48,000 springs in an 8-hour shift, this machine allows production speeds to finally match your sales team’s ambition.

- Intelligent Monitoring: Our real-time fault detection and magnetic spring steering system ensure that the assembly has a diagonal deviation of less than 1 cm—ensuring your final product is perfectly square and professional.

Part 6: Future Outlook & Synergy with Packing Tech

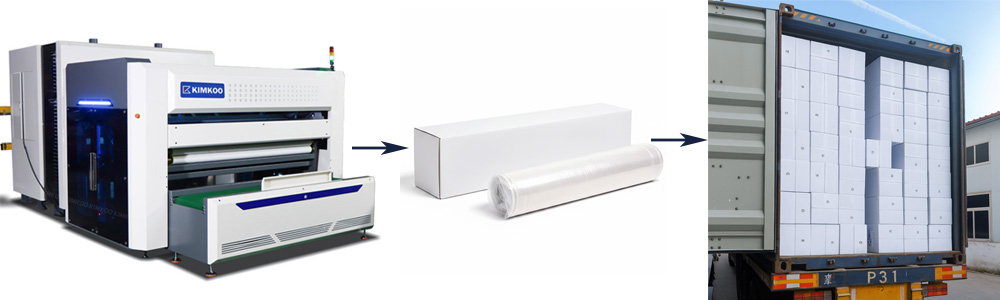

The future of the bonnell coil system is not just about making them, but about shipping them efficiently. Once your high-quality units are manufactured, the next step is logistics.

Even a heavy-duty Bonnell unit can be optimized for global export. After the spring unit is assembled into a mattress, leading manufacturers use an automated mattress roll packing machine to compress and roll the finished product. This synergy between the JK-BSA01 (Production) and the JK-CR1 (Packaging) is what allows China’s leading manufacturers to dominate the global “Bed-in-a-Box” market.

The Bottom Line

Whether you are exploring the bonnell spring mattress meaning for your retail store or researching how to manufacture a bonnell spring system for a new factory, understanding the balance between traditional support and modern automation is key.

As a premier Mattress Machine Manufacturer, KIMKOO provides the technology to turn raw materials into world-class sleep products. From coiling the first wire to the final roll-pack, we are your partner in bedding innovation.

Explore our full range of Bonnell Spring Solutions here or contact our engineering team to design your custom production line.