Description

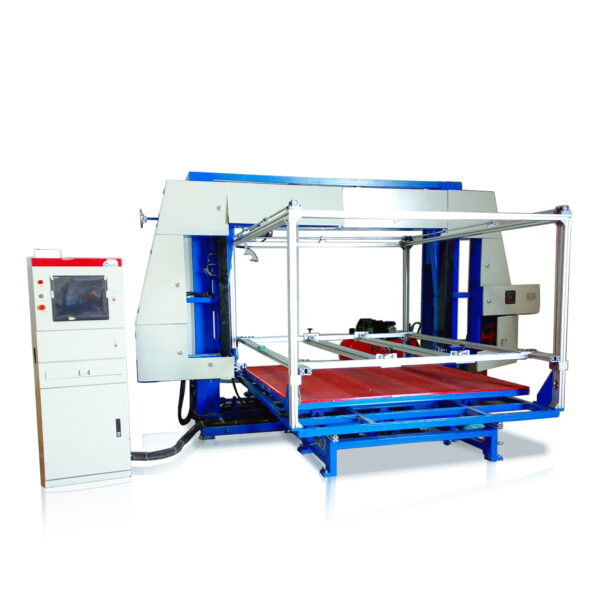

Introducing the JK-FC01, a state-of-the-art CNC foam contour cutting machine that revolutionizes the foam fabrication industry. Our cutting-edge technology seamlessly merges automated foam cutting CNC with advanced CAD functionalities, resulting in a myriad of advantages that set it apart in the market.

Precision and Speed Unleashed

Powered by high torque motors, the JK-FC01 boasts cutting speeds of up to 400+ inches per minute, ensuring rapid and precise fabrication of foam materials. The innovative dual-knife system, featuring both horizontal and vertical blades, enables the machine to swiftly create intricate 2D and 3D patterns. This unparalleled efficiency is further enhanced by the automation system, with the horizontal blade first splitting foam blocks into thinner sheets, followed by the vertical blade sculpting the foam to the desired pattern.

Efficiency Redefined

Designed for supreme efficiency, the CNC foam contour cutting machine minimizes manual labor with a computerized conveyor system at its core. This system requires only one operator per machine, optimizing workflow and reducing operational costs. Crafted with minimal moving parts, the machine ensures ultra-quiet operation and streamlined maintenance, allowing for unlimited growth potential for power users.

Versatility in Application

Primarily crafted for the production of ergonomic cushions and seat foam, the JK-FC01 is a versatile solution for a wide range of soft materials such as foam blocks, PU, PE, PVC, and more. Its adaptability makes it ideal for both small and large production of vacuum shapes, providing competitive pricing without compromising on quality.

Seamless Digital Operation

Operate the CNC patterns effortlessly with our software, offering digital control and precision. The optional digitizer board allows easy conversion of analog patterns into CAD, adding to the machine’s versatility.

CNC Contour Cutting Machine comes equipped with advanced features

- Adaptable Efficiency: Excelling in both small batch cutting and complex designs.

- Enhanced Mechanics: Revamped gearbox and internally fortified mechanics for swifter performance and superior cooling.

- Optimized Space Utilization: Integration of a new electrical cabinet within the worktable minimizes space occupancy while preserving high efficiency.

- Improved Transmission System: Cutting-edge transmission system for elevated stability, synchronization, and cutting precision.

- Maneuverable Console: A mobile console for easy observation and operation.

- Series Compatibility: Part of a unified series, enabling seamless collaboration for heightened automation levels, including automatic blade adjustment, zero calibration, processing range detection, and preemptive error detection, contributing to amplified production efficiency.

Invest in the JK-FC01 CNC foam contour cutting machine and experience the future of foam fabrication technology – where precision meets efficiency, and innovation meets versatility.

TECHNICAL PARAMETERS

| Cutting Foam Size | W2200mm*L2200mm |

| Cutting Foam Height | H1200mm |

| Cutting Foam Density | ≥50kg/CBM(+0.03-0.05mm) |

| Cutting Speed | 0~20m/min |

| Table Moving Type | 180℃ Rotatory Or Go And Back (To Be Requested) |

| Press Plate Device | One Set |

| Blade Length | L10750mm*W15mm*T0.65mm |

| Control Type | Computerized |

| Machine N.W | 2500kg |

| Total Motor Power | 8kw |

| Floor Space | L5000mm*W5000mm*H3300mm |