Description

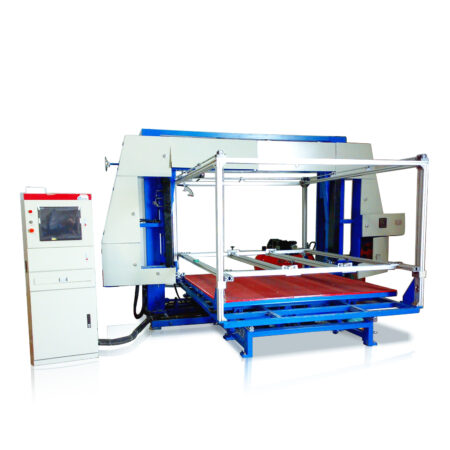

The horizontal foam cutting machine is equipped with a conveyor belt and a vacuum system, specially tailored for pu foam with exceptional detail and accuracy. Crafted with a robust welded steel frame, it incorporates essential pneumatic and electrical components, along with compression rollers to ensure precise cuts every time.

The JK-FC04 excels in its ability to handle foam cutting seamlessly, eliminating the need to remove foam slices from the working table after each cut. This fully automatic machine excels in both cutting and stacking PU foam, providing a hassle-free experience for operators. The conveyor surface facilitates lateral movement for a band knife to cut through materials, while a high-power suction system secures the foam in place, ensuring stability throughout the cutting process. This makes the JK-FC04 an invaluable addition to any foam cutting line.

Worked Materials

- Foam block cutting

- PU Foam, PE, PVC

- Other Soft Materials

Advantages: Compared to manual cutting machines, the JK-FC04 offers superior precision, allowing for thinner and more accurate cuts. The cutting thickness can be easily set to achieve the desired sponge thickness. With a user-friendly touch screen control system, manual cutting becomes obsolete, saving valuable time and increasing operational efficiency.

Horizontal Foam Cutting Machine Features:

- 1. Easy operation

- 2. Supports up to 1 fast wire

- 3. Adjustable cutting speed

- 3. Convenient blade clip electric elevator

- 4. Novel design, beautiful appearance, compact and reasonable structure

- 6. Anti-skid gravel surface on the conveyor belt prevents material sliding, ensuring even and consistent cutting

The JK-FC04 horizontal foam cutting machine stands out for its versatility, capable of converting foam blocks into sheets ranging from 2 mm to 200 mm in thickness. This machine is designed to meet the diverse needs of customers, making it an indispensable tool in the foam processing industry. Upgrade your cutting capabilities with the JK-FC04 for unparalleled precision, efficiency, and ease of operation.

TECHNICAL PARAMETERS

| 1650 Type | 2150 Type | ||

|---|---|---|---|

| Cutting Foam Size | W1650mm*L2000mm | Cutting Foam Size | W2150mm*L3000mm |

| Cutting Foam Height | H1200mm | Cutting Foam Height | H1200mm |

| Cutting Thickness | 2mm Up | Cutting Thickness | 2mm Up |

| Cutting Speed | 0~30m/min(Adjustable) | Cutting Speed | 0~30m/min(Adjustable) |

| Blade Length | L9640mm*W30mm*T0.45mm | Blade Length | L9640mm*W30mm*T0.45mm |

| Cutting Type | Automatic+Press Roller | Cutting Type | Automatic+Press Roller |

| Vacuum System | Available | Vacuum System | Available |

| Touchsreen System | Choose Available | Touchsreen System | Choose Available |

| Vacuum System | 7.5KW Choose Available | Vacuum System | 7.5KW Choose Available |

| Machine N.W | 2000kg | Machine N.W | 2500kg |

| Total Motor Power | 15w | Total Motor Power | 15w |

| Floor Space | L5000mm*W4000mm*H2400mm | Floor Space | L7000mm*W4500mm*H2400mm |