Description

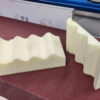

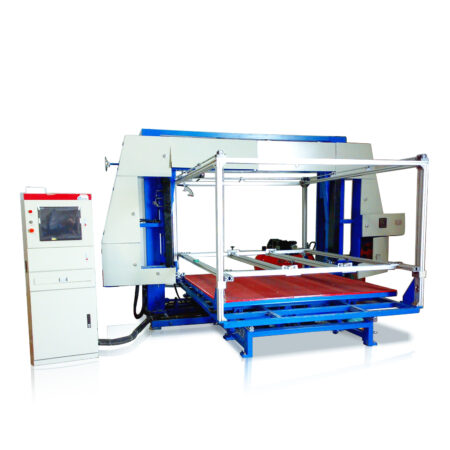

Introducing our manual foam contour cutting machine – the ideal solution for crafting different shapes of foam, from customized columns and curves to specialized pillows. This versatile machine boasts a range of features that make it suitable for various industries, including mattress manufacturing, logo creation, doll filling, and more.

Manual Foam Contour Cutting Machine Features

-

▲

- 1. Versatile Cutting Capability: Craft diverse foam shapes such as cylinders, arcs, pillows, and more using different templates. The machine is equipped with both vertical and horizontal knives to ensure precision in cutting various shapes.

- 2. Worked Materials: This manual foam contour cutting machine is designed to handle foam block cutting with ease. It is compatible with a variety of materials including PU, PE, PVC, and other soft materials.

- 3. Competitive Price: Offering a cost-effective alternative to CNC contour cutting machines, our manual foam cutter provides significant advantages in terms of pricing. Its semi-automatic operation is user-friendly and simplifies the cutting process, resulting in cost savings without compromising on quality.

- 4. Widely Used: Ideal for small-scale sponge cutting, the machine comes in two types to accommodate different customer needs. Whether you are engaged in mattress manufacturing or require precise foam cutting for various applications, this machine is versatile and can meet your requirements.

- 5. Easy Operation: With a simple handle and no need for extensive training, the manual foam contour cutting machine ensures ease of operation. The cutting speed is adjustable, and the height of the working table can be easily controlled, providing flexibility for different cutting requirements.

- 6. Customizable Moulds: Shape molds can be designed according to your specific needs, allowing for creative and intricate foam designs. This feature enhances the machine’s adaptability to various cutting tasks.

- 7. Convenient Blade Clip Electric Elevator: The machine features a blade clip electric elevator for easy and efficient handling. The cutting wire is readily available worldwide, ensuring convenience in maintenance and replacement.

- 8. Optional Features: Users can opt for additional features such as vacuum functionality and frequency adjustments based on their specific requirements.

- 9. Suitable for Various Materials: In addition to foam, this manual contour cutting machine is suitable for cutting small-size foam boards and processing materials like EVA, EPE, packaging materials, and paper, showcasing its versatility across multiple applications.

- 10. High Cutting Precision: The manual operation on the worktable ensures high cutting precision, making this machine a reliable choice for foam manufacturing and other related industries.

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

Upgrade your foam cutting capabilities with our Manual Foam Contour Cutting Machine, offering a perfect balance of affordability, versatility, and precision in foam crafting.

TECHNICAL PARAMETERS

| 1000 Type | 2000 Type | ||

|---|---|---|---|

| Cutting Foam Size | W1000*L1000*H600mm | Cutting Foam Size | W2000*L1000*H600mm |

| Cutting Type | Wire Cutting Type | Cutting Type | Wire Cutting Type |

| Cutting Speed | 0-10m/min(Manual Control) | Cutting Speed | 0-10m/min(Manual Control) |

| Wire Length | L5700mm*Dia1.5mm | Wire Length | L5700mm*Dia1.5mm |

| Machine N.W. | 1000kg | Machine N.W. | 1200kg |

| Total Motor Power | 1.5Kw | Total Motor Power | 1.5Kw |

| Floor Space | L2500*W2300*H1200mm | Floor Space | 4000*W2500*H1200mm |

KIMKOO Mattress Machinery