Description

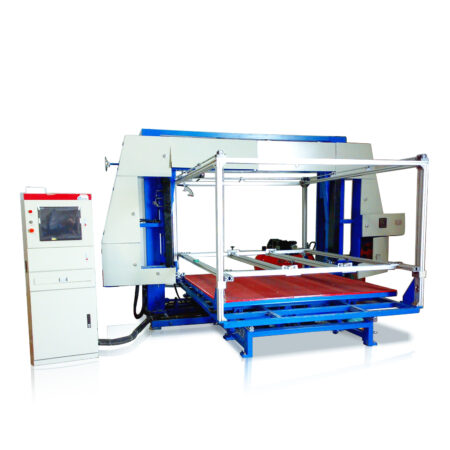

Zimlin specializes in delivering top-notch and efficient products that conform to both China and international quality benchmarks. Our circular foam cutting machines are designed to fulfill the essential task of transforming raw foam into precise sheets. Constructed with a cutting unit crafted from high-quality stainless steel, our machines boast durability and resistance to corrosion.

▲

These Circular Cutting Machines are meticulously engineered to accurately cut foam of various thicknesses. Featuring a fixed cutting portion and a circular tabletop, these machines are powered by an AC motor controlled by a PLC for precise rotations. During operation, PU foam blocks are strategically positioned on the circular table, which, in turn, moves in a circular motion. This movement allows the PU foam blocks to be cut into the desired size and thickness.

▲

Our Circular Foam Cutting Machines are adept at handling high production volumes, showcasing the efficiency of Zimlin devices. Designed by a team of seasoned professionals with extensive experience, our circular foam cutting machines have gained a reputation for their reliability and precision.

Circular Foam Cutting Machine Features

- 1. High Yield Capacity: The machine can handle up to 10-12 blocks, providing a high yield based on the specific needs.

- 2. Adjustable Cutting Speed: The cutting speed is customizable, allowing for flexibility in different cutting requirements.

- 3. Easy to Operate: The machine is designed for user-friendly operation, with automatic control features.

- 4. Durable Structure: The construction of the cutting machine is built to withstand wear and tear, ensuring long-lasting durability.

- 5. Vacuum System: A vacuum system is incorporated to hold and stabilize foam blocks on the table during the cutting process.

- 6. Material: Mild steel is used in the manufacturing of the cutting unit, likely contributing to the machine’s robustness.

- 7. Rotary Slitting Table: The machine features a rotary slitting table with a wooden tabletop that has a friction surface.

- 8. Variable Table Speed Control: The table speed can be adjusted infinitely, ranging from 0 to 5 rpm, facilitated by a variable frequency drive.

- 9. Electric Blade Drive Motor: The cutting unit is equipped with an electric blade drive motor for efficient cutting.

- 10 Control Panel: A control panel with a Programmable Logic Controller (PLC) and a touch screen is included for easy and precise control of the machine.

- 11. Blade Breakage Detector: The machine is equipped with a blade breakage detector that automatically shuts off the machine in case of blade breakage, enhancing safety.

- 12.Teflon Coated Blade Guide: The blade guide is coated with Teflon (PTFE), which is known for its nonstick and high-temperature resistance properties.

TECHNICAL PARAMETERS

| 1650 Type | 2150 Type | ||

|---|---|---|---|

| Cutting Foam Size | W1650mm*L2000mm | Cutting Foam Size | W2150mm*L3000mm |

| Cutting Foam Height | H1200mm | Cutting Foam Height | H1200mm |

| Cutting Thickness | 2mm Up | Cutting Thickness | 2mm Up |

| Cutting Speed | 0~30m/min(Adjustable) | Cutting Speed | 0~30m/min(Adjustable) |

| Blade Length | L9640mm*W30mm*T0.45mm | Blade Length | L9640mm*W30mm*T0.45mm |

| Cutting Type | Automatic+Press Roller | Cutting Type | Automatic+Press Roller |

| Vacuum System | Available | Vacuum System | Available |

| Touchsreen System | Choose Available | Touchsreen System | Choose Available |

| Vacuum System | 7.5KW Choose Available | Vacuum System | 7.5KW Choose Available |

| Machine N.W | 2000kg | Machine N.W | 2500kg |

| Total Motor Power | 15w | Total Motor Power | 15w |

| Floor Space | L5000mm*W4000mm*H2400mm | Floor Space | L7000mm*W4500mm*H2400mm |